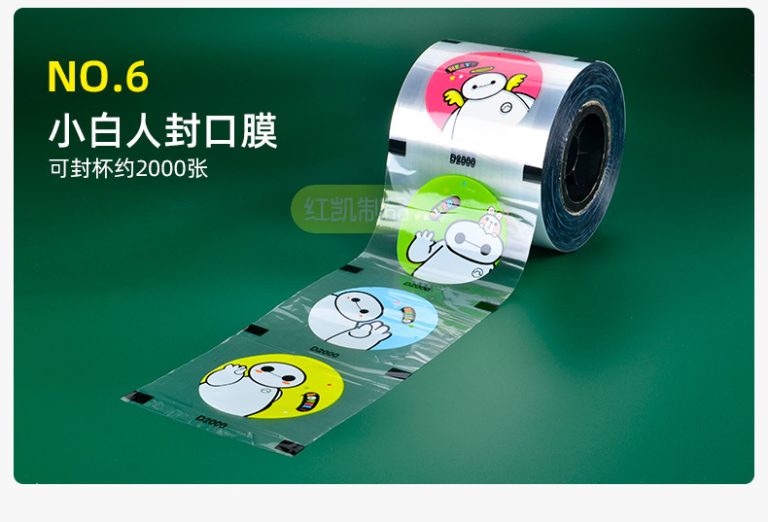

Materials used for Food Packaging Bags

Food packaging bags play a crucial role in preserving the quality and safety of food products. They serve as a barrier against external contaminants, moisture, and oxygen, which can degrade the quality of the food inside. To ensure that food packaging bags are effective in protecting the contents, certain requirements must be met in terms of materials used, design, and manufacturing processes.

One of the most important requirements for food packaging bags is that they must be made from materials that are safe for food contact. This means that the materials used in the production of food packaging bags must not leach harmful chemicals or substances into the food. Common materials used for food packaging bags include polyethylene, polypropylene, and polyester. These materials are known for their durability, flexibility, and resistance to moisture and oxygen.

In addition to being safe for food contact, food packaging bags must also be able to provide a barrier against external contaminants. This is especially important for perishable food products that are sensitive to moisture, oxygen, and light. To achieve this, food packaging bags are often made with multiple layers of materials, each serving a specific purpose. For example, some food packaging bags have a layer of aluminum foil to provide a barrier against oxygen and light, while another layer of polyethylene provides a seal against moisture.

Another requirement for food packaging bags is that they must be able to withstand the rigors of transportation and storage. Food products are often shipped long distances and stored in various conditions, so it is important that the packaging bags are durable and resistant to punctures, tears, and leaks. To meet this requirement, food packaging bags are often designed with features such as strong seals, reinforced corners, and tear-resistant materials.

| Place of Origin | China |

| Industrial Use | Food |

| Size | Custom Size Accepted |

| LOGO | Customized Logo Acceptable |

Furthermore, food packaging bags must be designed in a way that is convenient for consumers to use. This includes features such as easy-open seals, resealable closures, and clear labeling. Consumers should be able to easily access the food inside the packaging bag without causing damage to the bag itself. Additionally, clear labeling is important for providing information about the contents of the bag, including expiration dates, nutritional information, and storage instructions.

In terms of manufacturing processes, food packaging bags must be produced in facilities that adhere to strict quality control standards. This includes ensuring that the materials used are of high quality, the production processes are sanitary, and the finished products are free from defects. Food packaging bags may also need to undergo testing to ensure that they meet regulatory requirements for food safety and quality.

Overall, the requirements for food packaging bags are stringent to ensure that they effectively protect the quality and safety of food products. By using safe materials, providing a barrier against contaminants, ensuring durability, and designing for consumer convenience, food packaging bags play a vital role in the food industry. Manufacturers and consumers alike must be aware of these requirements to ensure that food packaging bags meet the necessary standards for protecting food products.