Table of Contents

Benefits of Using Uline PVC Shrink Film Roll for Packaging

Packaging plays a crucial role in protecting products during storage and transportation. It not only ensures the safety of the items but also serves as a marketing tool to attract customers. When it comes to packaging, using the right materials is essential to achieve these goals. One popular option for packaging is PVC shrink film rolls, and Uline is a trusted brand known for its high-quality products.

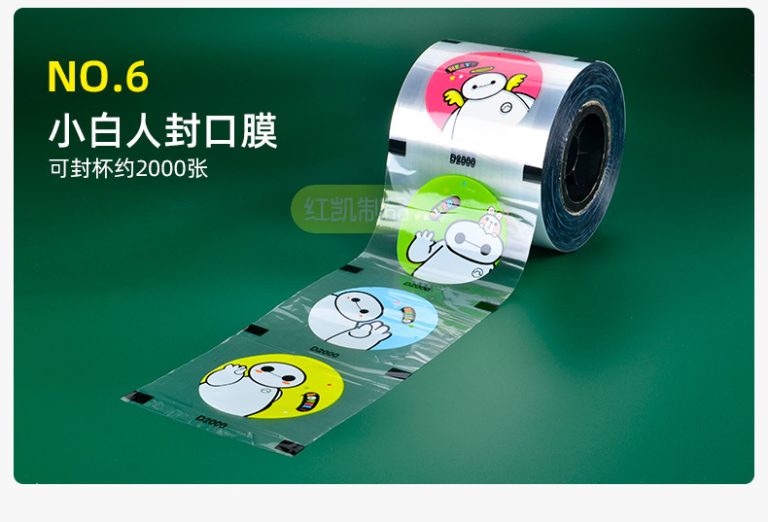

Uline PVC shrink film rolls offer a range of benefits that make them an ideal choice for packaging various items. One of the key advantages of using PVC shrink film is its durability. PVC is a strong and resilient material that can withstand rough handling and protect products from damage. This makes it an excellent choice for packaging fragile or delicate items that require extra protection during transit.

In addition to its durability, Uline PVC shrink film rolls are also highly versatile. They can be used to package a wide range of products, from food items to electronics to household goods. The flexibility of PVC shrink film allows it to conform to the shape of the product, creating a snug and secure fit that helps prevent shifting or damage during shipping.

| Origin | China |

| Transparency | Transparent |

| Type | Blow Molding |

| LOGO | Customized Logo Acceptable |

Another benefit of using Uline PVC shrink film rolls is their clarity. PVC shrink film is transparent, allowing customers to see the product inside without having to open the package. This can help attract customers by showcasing the quality and appearance of the item, leading to increased sales and customer satisfaction.

Furthermore, Uline PVC shrink film rolls are easy to use and apply. They can be used with a heat gun or shrink wrap machine to quickly and efficiently package products. The shrink film shrinks tightly around the product when heat is applied, creating a professional and polished look that enhances the overall presentation of the item.

In addition to their practical benefits, Uline PVC shrink film rolls are also environmentally friendly. PVC is a recyclable material, making it a sustainable choice for packaging. By using PVC shrink film, businesses can reduce their environmental impact and demonstrate their commitment to sustainability.

Overall, Uline PVC shrink film rolls offer a range of benefits that make them an excellent choice for packaging. From their durability and versatility to their clarity and ease of use, PVC shrink film provides a reliable and effective solution for protecting products during shipping and storage. By choosing Uline PVC shrink film rolls, businesses can ensure that their products arrive safely and securely to customers, while also enhancing the overall presentation and appeal of their items.

How to Properly Use Uline PVC Shrink Film Roll for Shrink Wrapping Applications

Shrink wrapping is a popular packaging method used in various industries to protect products during storage and transportation. One of the key components of shrink wrapping is the shrink film roll, which is used to encase the product and then shrink down to create a tight, protective seal. Uline PVC shrink film rolls are a popular choice for shrink wrapping applications due to their durability and versatility.

When using a Uline PVC shrink film roll for shrink wrapping, it is important to follow a few key steps to ensure a successful packaging process. First and foremost, it is essential to choose the right size of shrink film roll for the product being wrapped. The shrink film should be large enough to fully encase the product with some extra material for sealing, but not so large that it creates excess waste.

Once the appropriate size of shrink film roll has been selected, the next step is to properly prepare the product for wrapping. This may involve cleaning the product, removing any excess packaging materials, and ensuring that the product is properly positioned on the shrink film. It is important to take care when handling the shrink film to avoid tearing or damaging it before it is properly sealed.

After the product has been prepared, it is time to seal the shrink film around the product. This can be done using a heat sealer or a shrink wrap machine, depending on the size and volume of products being wrapped. When using a heat sealer, it is important to apply even pressure along the edges of the shrink film to create a tight seal. If using a shrink wrap machine, be sure to follow the manufacturer’s instructions for proper operation.

Once the shrink film has been sealed around the product, it is time to apply heat to shrink the film down and create a tight, protective seal. This can be done using a heat gun or a shrink wrap tunnel, depending on the size and volume of products being wrapped. When using a heat gun, be sure to move it evenly and consistently over the shrink film to avoid creating hot spots or uneven shrinking. If using a shrink wrap tunnel, be sure to set the temperature and speed settings according to the manufacturer’s instructions.

After the shrink film has been properly shrunk down, it is important to allow the product to cool before handling or moving it. This will ensure that the shrink film has fully adhered to the product and created a secure seal. Once the product has cooled, it can be labeled, stacked, and prepared for storage or transportation.

In conclusion, using a Uline PVC shrink film roll for shrink wrapping applications can help protect products and ensure their safe delivery to customers. By following the proper steps for selecting, preparing, sealing, and shrinking the shrink film, you can create a professional and secure packaging solution for your products. Remember to always follow the manufacturer’s instructions and guidelines for using shrink film rolls to achieve the best results.